Process measurement with MBA Instruments

Measuring devices for level measurement in bulk silos and conductivity measurement in mineral oils pipelines and tanks.

Patented instrumentation, reliable workmanship, optimised to the essentials:

Precise measured values - always accurate to the point.

Measurement Systems. Simplified.

Robust level switches and precise conductivity measuring devices

MBA Instruments combines many years of expertise, quality and reliability.

We can look back on a long and successful tradition in process measurement technology. The foundation for this was laid by our revolutionary "Maihak" rotary paddle level indicator, which proudly celebrated its 80th anniversary in 2019.

We would be happy to give you an insight into our expertise.

Level measurement for bulk solids

Whether the focus is on checking fill levels in bucket elevators, bunkers and storage silos or ensuring the safety of ship loaders with hoppers or for transfer stations between transport containers, our level measurement technology is successfully used for sand, powder, stones, glass, wood and granulates with often explosive properties.

Conductivity measurement in mineral oils

We provide you with systems for the continuous and stationary conductivity measurement of fuels and products containing mineral oil. Our measuring devices are designed in particular for conductivity measurements in light mineral oils such as turbine fuel (paraffin, Jet A-1) or rolling oil and are listed, certified and approved in ASTM2624.

Areas of application for MBA level measurement technology

We manufacture customised measuring devices that perfectly meet the needs of our customers in terms of geometry, measuring performance and economic requirements. Our process instrumentation for level measurment are used successfully in a number of industries and for various applications, especially in bulk silos of all kinds.

The requirements for food manufacturers are very high, particularly in terms of hygiene standards. In addition to production, appropriate hygiene regulations must also be adhered to when storing products. The quality of stored products, such as sugar, flour or grain, can be significantly impaired by the formation of condensation. The level measurement system from MBA Instruments has been specially developed for use in hygienic environments, as required in the food industry. Designed for universal use, the measuring instruments take into account the respective properties of the stored product as well as product-specific boundary conditions.

In the wood processing industry, level measuring devices play a crucial role in ensuring that production processes run smoothly. Our solutions enable precise monitoring of fill levels in silos, tanks and storage facilities for wood and wood products. Our many years of experience in working with companies in the wood processing industry make us a valued partner.

Level monitoring in the storage facility (e.g. silo) is essential for the smooth storage of building materials. MBA's precise measurement technology makes a significant contribution to the cost-efficient storage of building materials such as cement, sand or gravel. Our measuring instruments are robust and reliable, especially in dusty environments and in processes with high temperatures.

We are a partner for companies and organisations in the field of waste technology. Our diverse customer base in this sector covers various areas, including waste disposal companies, recycling plants, landfill sites and municipal facilities.

Our level measuring devices are designed to meet the specific requirements of waste technology. They offer accuracy, reliability and resistance to the environmental conditions encountered in this sector.

We understand the challenges faced by companies in the mining and extraction of raw materials. Our level measurement devices are designed to withstand the extreme conditions and high demands of this industry. They offer reliability and accuracy to ensure the smooth operation and safety of mining and raw material extraction plants. Our customer base in this industry spans mining companies, raw material producers and plant operators worldwide.

Our level measurement devices are crucial for companies in the chemical industry as they enable accurate monitoring and control of liquid and product levels. Our many years of experience and in-depth understanding of the requirements of the chemical industry have made us a trusted partner for numerous companies in this sector.

At MBA Instruments, we are proud to serve a wide range of customers in the transport, distribution and logistics sector. Our customer base in this industry spans various sectors, including haulage companies, freight forwarders, warehouses and logistics service providers, and our high-quality level measurement devices and solutions have proven themselves in this demanding sector to ensure that transport and storage processes run smoothly.

Areas of application for MBA conductivity measuring devices

Whether as manual or continuous in-line measurement in pipelines and tanks - the technology of our conductivity measuring devices has been tried and tested in use worldwide for several decades and enables the precise supply of additives.

When handling petroleum products with low electrical conductivity, such as paraffin as a fuel in commercial aviation, high electrostatic charging can occur. The measurement of electrical conductivity is a prerequisite for the high safety regulations when handling the fuel. MBA Instruments develops robust conductivity measuring instruments especially for these applications.

Highly developed precision machines are used in metal production and processing. The machines must be particularly wear-resistant to ensure consistent quality results. Lubricating oils (e.g. rolling oil) are used. To avoid electrostatic discharge, conductivity must be continuously monitored. MBA Instruments develops measuring instruments that are designed, certified and approved for conductivity measurement of lubricating oils.

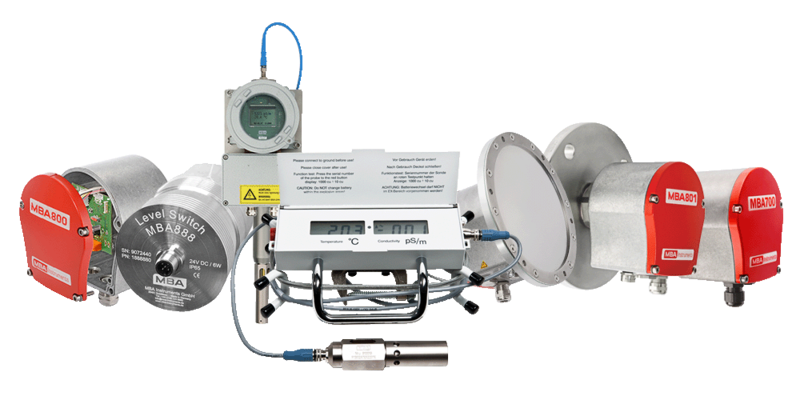

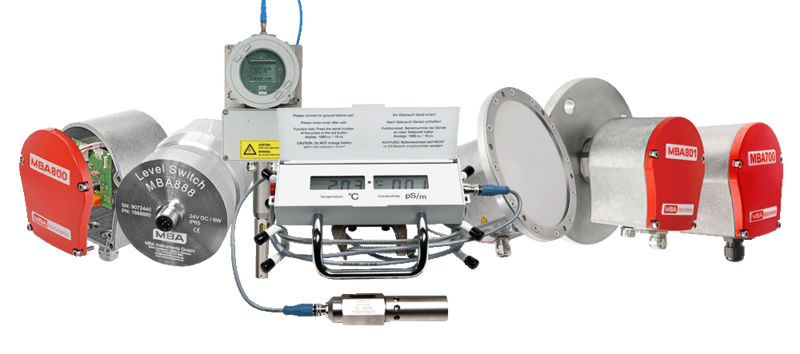

MBA products

Process instrumentation for demanding environmental and process conditions is our speciality.

At MBA Instruments, we specialise in customised process measurement technology for level measurement and conductivity measurement. When selecting the right measuring devices, we advise you on suitable measuring methods and show you the greatest possible scope of application for your areas of use.

Get an overview of our product portfolio:

Measurement technology made in Quickborn

Whether in the market launch of special applications and new developments or the sale of proven technology - we realise individual solutions for your applications with consistently high quality. Our wide range of measuring devices is manufactured in our factory in Quickborn.

MBA: Your partner for precise measurement technology

If you get something "to the point", you get it just right - not too much and not too little, not too strong and not too weak. In the field of measurement technology, this means always keeping an eye on all the important parameters, knowing what they mean and drawing the right conclusions. There is no room for error here, no room for inaccuracy, no both/and. Precision and clarity are the fundamental tasks of fill level and conductivity measurement and the challenge we solve for you! #tothepoint

How do we achieve this? With precise and proven measuring devices that are optimised for a wide range of requirements and applications: Our point level measurements simplify measurement processes and operating procedures, while our conductivity measuring devices minimise hazards, workload and costs. The starting point for our work is the efficiency and safety of measuring processes. We focus on the optimum combination of application, requirements and measurement technology.

When are we satisfied? When all the devices used fulfil their task flawlessly and give our customers one thing: The good feeling of having got everything "to the point"!

October 2024: MBA at the Solids 2024 in Dortmund

MBA is at the trade fair for granulate, powder and bulk solids technologies!

October 2023: MBA Instruments at the Inter Airport Europe in Munich

The international trade fair for airport equipment, technology, design and services will take place for the 24th time from October 10 to 13, 2023.

October 2023: MBA at the ADIPEC 2023 in Abu Dhabi

The Abu Dhabi International Petroleum Exhibition and Conference (ADIPEC) will take place from October 2 to October 5, 2023.