Legacy products

Level measuring devices from SICK MAIHAK AG

MBA Instruments specialises in devices for level measurement. In addition to our reliable rotary paddle technology, the product portfolio also includes membrane switches, level measuring devices with radar, oscillating paddles and rotating paddles as well as the plumb bob system. Our selection is constantly being supplemented by new and further developments, because even proven devices benefit from innovations: In this list you will find the link to the optimised original successor to a discontinued product. This makes it easy for you to find the most suitable model for your purposes.

Point level measurement devices

These point level measurement products are no longer part of our portfolio. Corresponding original successors or further developments can be found in the references provided.

MBA808

Level measurement with pouring cone smoothing

The possibilities of stepper motor technology are fully utilised here. While a very large vane levels the bulk solids evenly with great force during filling and pushes them in a circular motion towards the inner wall of the silo, the previously unused flanks of the bulk cone are also filled. The MBA808 only sends the additional signal "silo completely full" when no more cone of debris can form and the silo is completely full. The "2 in 1" model of the MBA800 electronic rotary paddle series offers two functions in one device. With continuous filling, it levels the pouring cone with its own power and then emits a signal when the silo is full. The result is optimum utilisation of the silo volume. Like all devices in the MBA800 series, the MBA808 is also based on stepper motor technology.

Further developments of the MBA800 rotary paddle series can be found on our overview page:

MBA200

Level switch "Maihak type"

Robust, safe and reliable - for more than 70 years, rotary paddle level switches of the Maihak type have proven their worth. The level indicator switches as a full, demand and empty indicator for bulk solids in both large storage silos and small containers. In downpipes and conveyor systems, it signals a backlog in the product flow in good time. It has an energy-saving AC motor: when the rotary paddle is stopped, the motor switches off automatically and is not loaded when stationary. It is used for various bulk solids such as granulates, animal feed, spices or powders.

All functions are continued by its original successor, the digital rotating paddle detector MBA800, in proven state-of-the-art quality.

MBA20

Level switches

MBA series level switches are robust electromechanical sensors that detect the presence of bulk solids at the installation location. They are designed to monitor the filling of a bulk goods container. The possible applications depend on the individual device design. Variable are e.g:

- Design and size of the device (= device type)

- Size, shape and material of the rotary paddle

- Material and design of the rotating shaft

- Sealing between housing and rotating shaft

- Safety standard (e.g. explosion protection)

- Permissible operating temperature

All the functions of the MBA20 are continued by its original successor, the digital rotating paddle detector MBA888, in proven state-of-the-art quality.

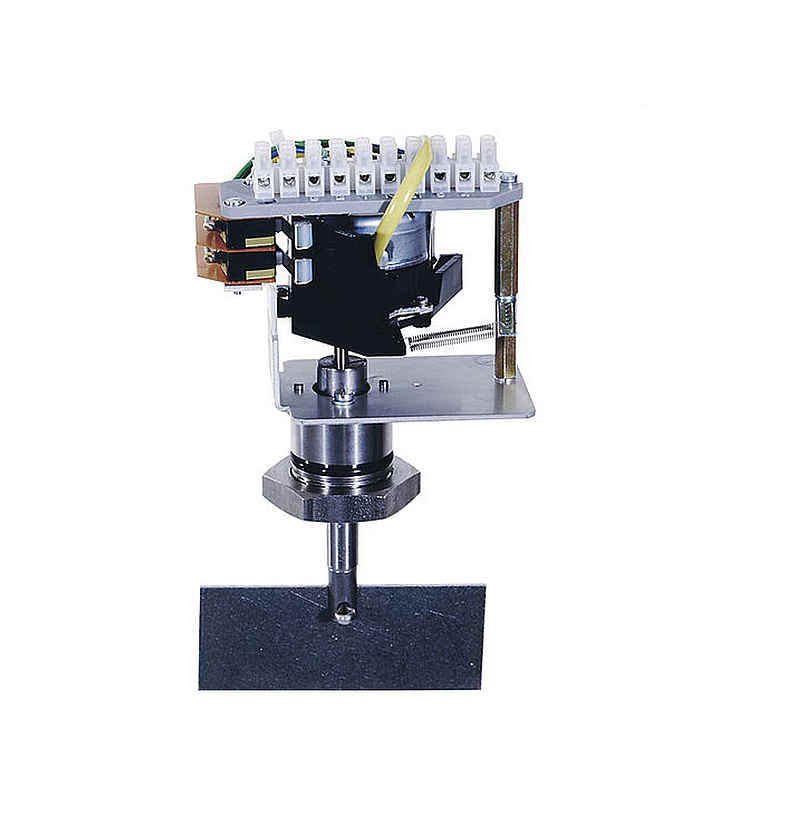

MBA5

Level indicator

An MBA level switch consists of an indicator head and a bracket. The head contains the electrical and electromechanical components; it is attached to the outer wall of the bulk container. The bracket projects into the bulk container. It consists of a shaft with a blade and, depending on the version, a protective tube and support bearings for the shaft. The electric motor in the indicator head causes the shaft and vane to rotate slowly. When the bulk solids enclose the vane, it blocks the rotation. The counter torque is used to turn the motor mechanism against a switch, which then switches the motor off. The switch has a second contact (potential-free) for signalling the status.

All the functions of the MBA5 are continued by its original successor, the digital rotating paddle detector MBA800, in proven state-of-the-art quality.

MBA 2.2/3.2

Rotary paddle level switches "Maihak type"

The MBA 2.2 and MBA 3.2 devices are ATEX-certified rotary paddle level switches that are used in dust Ex zone 20 with simultaneous gas Ex zone 1 and impress with their robust design. The MBA 2.2 (vertical version) and the MBA 3.2 (horizontal version) are particularly suitable for measuring the point levels of granulate, dust or sludge when a gas Ex zone is present at the same time, for example due to solvent vapours. A measuring blade is driven by a synchronised gear motor and stops as soon as it is covered by the product. When the fill level drops, the rotary paddle is released again.

Our further developments of the MBA 2.2 and MBA 3.2 level measuring devices can be found on our overview page:

Other level measuring devices

These continuous level measurement devices are no longer part of our product portfolio. Alternative measuring devices can be found under the links provided.

MBA300

Radar for continuous level measurement

The principle of measurement of the MBA300 is based on radar pulses that are reflected by the bulk solids. The MBA300 is used in the food and construction industries, plastics processing and steel production, among others. This type of continuous level measurement does not require any contact with the bulk solids. The radar level switch can be used in containers up to 15 metres high.

For detailed information and alternative products, please visit our overview page:

MBA400

Continuous level measurement with radar

The radar measuring method of the MBA400 enables precise and reliable level measurement in narrow containers or in containers with fixtures. No stirring of the bulk solids is required for level measurement. By emitting radar pulses onto the bulk solids, their surface reflects the signals. The transit time measurement is proportional to the fill level. The radar level switch can be used in silos up to 75 metres high. Areas of application include the food, chemical and construction industries as well as plastics processing and steel production.

General information about radar measurement can be found on our overview page:

MBA369

Plumb bob system semi-continuous measurements

The MBA369 plummet system enables level measurement in all bulk solids. The height of sediments below the surface of liquids can be determined using a sieve weight. It is also suitable for continuous level measurement of a liquid level.

You can find information about perpendicular measurement on our continuous level measurement with perpendicular: