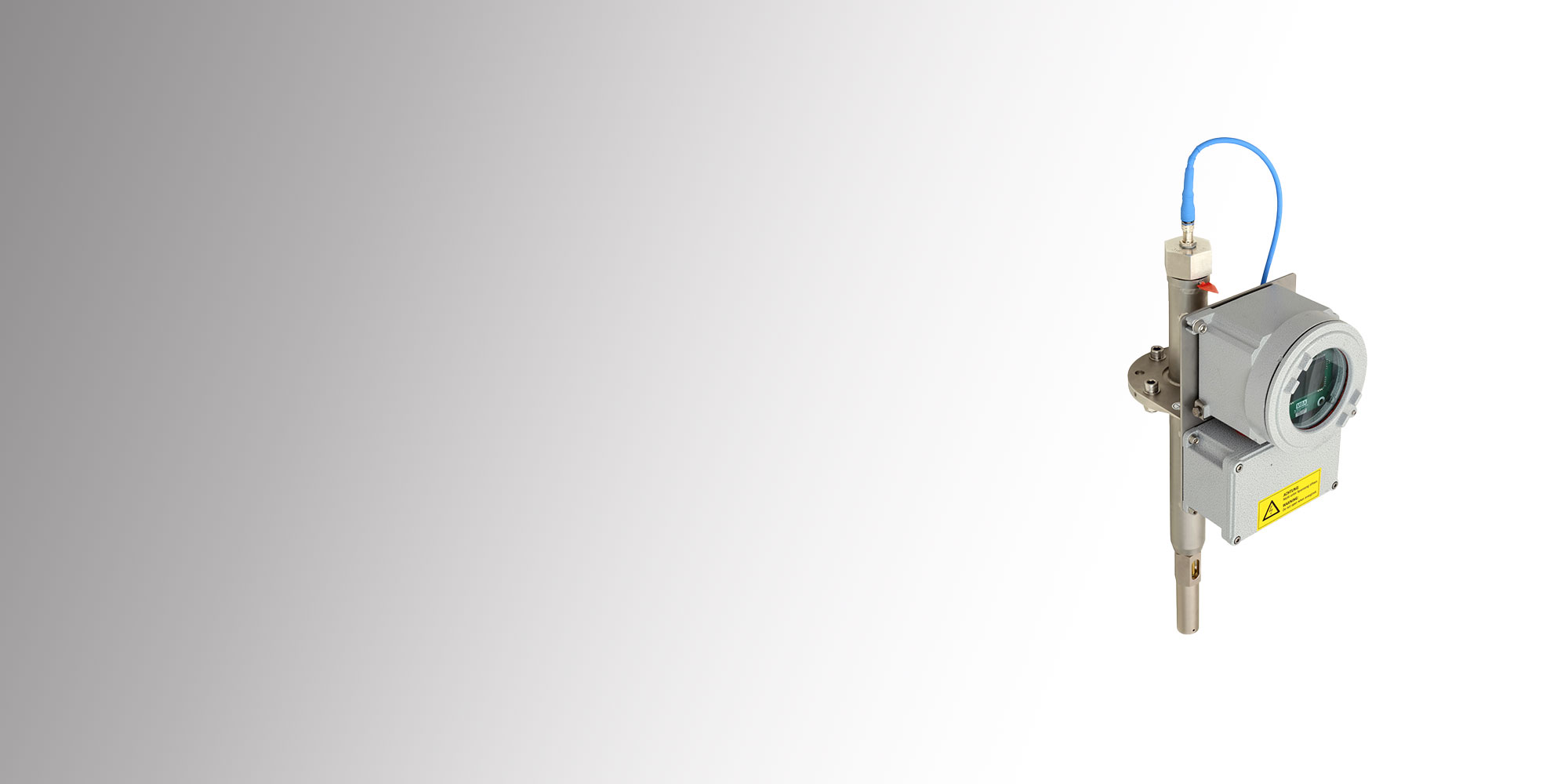

MLA1000

Continuous measurement of electrical conductivity in oil

Safety through stationary measurement

Light mineral oils such as kerosene are handled via pipelines on their way from the refinery via the tank farm to the airport site; rolling or hydraulic oils flow via ring lines through pumps and filters to the storage tank. As these oils have a low conductivity, the risk of electrostatic charging is very high.

By stationary measurement of the electrical conductivity value in oil with the MLA1000, airports, pipeline operators or refueling companies can improve the safety of fuel transport and reduce the use of additives. Light mineral oils can be tested in-line, directly and continuously.

Silicone oils and solvents in technical and industrial applications are also among the standard applications of the conductivity meter.

Find out more about the MLA1000! Important information and details about the product can be downloaded here.

Brochure conductivity measurement Operating instructions MLA1000Product information

- Electrical conductivity: up to 15,000 pS/m; simultaneous temperature measurements from -20 °C to 60 °C Limit value message

- Output signal: 4..20mA for electrical conductivity and temperature

- Display unit MLA1000-A: II 2(1)G Ex de [ia Ga] IIB T4 Gb and probe MLA1000-S: II 1G Ex ia IIB T4 Ga equipped with ATEX and IECXs approval

- Simple checking of function and display accuracy

- Separate mounting of the display possible

Stationary measuring system for high safety requirements

The Technical Rule for Hazardous Substances TRGS 727 describes the "safe handling of liquids and the avoidance of ignition hazards due to electrostatic charges". This technical guideline recommends checking and documenting conductivity in the event of electrostatic charge hazards.

The MLA1000 is able to measure the average conductivity of 50 - 15,000 picosiemens/meter (pS/m) and thus ensures a high level of safety when pumping and handling hazardous liquids. The measured values for temperature and conductivity are also output as a 4...20mA signal and on the display. A sliding sleeve for adjusting the immersion depth and for changing the probe under process conditions is optionally available. Jet A-1 kerosene is used as aviation turbine fuel in commercial aviation worldwide, while Jet B kerosene is used in military aviation - these fuels are therefore relevant for international airlines as well as industrial customers such as turbine manufacturers.

The MLA1000 can be used, for example, for

- Kerosene Jet A-1

- Hydraulic oils

- Silicone oils

- Solvents

- Rolling oils